Understanding Deck Stain: Impact of Hot Summers on Longevity

deck restorationdurable finishindustry standardssummer conditionsconditions

Summer Heat and Paint and Stain on Decks

Introduction

Deck surfaces are an essential part of maintaining a beautiful and functional outdoor living space. Homeowners and business proprietors alike rely on quality wood restoration and refinishing services to protect their decks from natural wear and tear. However, one of the most significant challenges in deck maintenance arises during the summer months. Intense heat, prolonged sunlight, and high humidity can affect the adhesion, appearance, and durability of deck paints and stains. This article explains how summer conditions impact deck coatings and offers expert advice on product selection, application techniques, and ongoing maintenance practices to ensure decks remain attractive and well-protected.

In summer, high temperatures and ultraviolet rays can cause deck coatings to deteriorate faster than usual. Homeowners often face premature fading, cracking, and peeling that compromise both the look and longevity of the deck. This article explains the interactions between wood substrates and deck finish formulations, clarifying the physics behind wood expansion and contraction, accelerated drying times, and other common issues.

TimberSeal Inc., with nearly 30 years of experience in wood restoration and refinishing, offers valuable insights into the challenges summer heat poses to deck surfaces. We analyze the risks of applying deck stain and paint in direct summer heat and provide practical, scientifically informed strategies to maximize finish durability. By understanding the science behind deck maintenance and following our recommendations, homeowners can achieve a long-lasting, high-quality finish that withstands even the most extreme summer conditions.

Transitioning to the main content, the following sections delve into summer’s impact on deck coatings, proper product selection, application best practices, maintenance tips, and common coating problems. This detailed guide will help you optimize

efforts and ensure your deck remains beautiful and protected all summer long.

Understanding How Summer Heat Affects Deck Paint and Stain

Summer weather significantly affects the performance and longevity of deck paint and stain. High temperatures compromise coating adhesion, while intense sun accelerates fading. The heat causes the wood substrate to expand and contract, stressing the finish and making it prone to cracking and peeling. Research indicates that coatings applied above the recommended temperature can lose up to 40% of their intended durability. These effects are compounded by humidity and direct sunlight, which degrade the protective film on the deck.

The Impact of High Temperatures on Deck Coating Adhesion

High ambient temperatures can cause rapid drying of deck coatings. When applied in intense heat, the solvent in the stain or paint evaporates too quickly, preventing proper penetration and bonding with the wood fibers. This compromised adhesion can result in blistering, peeling, and premature failure. Field studies show that coatings applied at temperatures exceeding 90°F may experience a 30% drop in adhesion strength.

How Intense Sun Exposure Accelerates Fading of Deck Stain and Paint

Ultraviolet (UV) radiation is a primary factor in the fading of deck finishes. Prolonged sun exposure causes pigments and organic compounds in stains and paints to break down over time. This photodegradation results in a noticeable loss of color intensity and can alter the original finish. Finishes lacking adequate UV inhibitors are at a higher risk of rapid fading, whereas those with UV blockers may extend vibrancy by up to 50%.

Increased Risk of Cracking and Peeling for Deck Paint in Summer

Heat-induced wood expansion and contraction can lead to micro-cracks beneath the deck finish. As the wood moves with temperature shifts, brittle finish layers cannot flex accordingly, resulting in cracks that eventually cause larger peeling areas. This problem is particularly common with painted surfaces that form a rigid film. Manufacturers recommend applying deck coatings within specified temperature ranges to minimize these risks.

How Humidity Combined With Heat Influences Deck Stain Drying Times

Humidity plays a crucial role in the drying process of deck stains and paints. In high-humidity environments, moisture slows solvent evaporation, extending drying periods. Conversely, in hot, dry climates, rapid drying may occur. Both extremes can be detrimental: slow drying increases dust adhesion, while fast drying hinders the formation of a uniform film. A proper balance is essential for a

.

Wood Expansion and Contraction in Summer and Its Effect on Finishes

Wood naturally expands and contracts with environmental changes. During summer, high temperatures and fluctuating humidity cause the deck to expand more and then contract as temperatures drop. This continuous movement places mechanical stress on the coating, challenging its adhesion. Experts recommend allowing the wood to acclimate to temperature changes before applying any finish and using products formulated to tolerate such movements.

Selecting the Right Deck Stain for Optimal Summer Performance

Choosing the appropriate deck stain is critical for optimum performance in hot weather. Not all deck stains are created equal, and selecting one designed for summer conditions can mitigate many temperature-related problems.

Choosing a Deck Stain With UV Protection for Sunny Conditions

UV protection is essential to prevent fading and premature degradation. Stains with UV inhibitors, such as titanium dioxide or zinc oxide, reflect harmful rays, extending the life of the finish. These UV-protected stains help maintain the color and integrity of the deck, especially when exposed to direct sunlight. Homeowners should verify that the product meets

for UV resistance.

Benefits of Lighter Colored Deck Stains in Reducing Heat Absorption

Lighter colors absorb less heat than darker shades. Choosing a lighter deck stain can reduce the thermal load on your deck surface, leading to lower expansion and contraction rates. This not only preserves finish integrity but also keeps the deck cooler to the touch. Empirical evidence suggests lighter surfaces can be up to 20% cooler than darker ones, reducing overall stress on the coating. stain colors

Considering Oil-Based Versus Water-Based Deck Stains for Hot Weather

The choice between oil-based and water-based deck stains depends on environmental conditions and desired durability. Oil-based stains typically penetrate deeper into the wood and offer robust protection against UV rays and water infiltration, though they require longer drying times and are sensitive to high temperatures. Conversely, water-based stains dry faster and produce a more uniform finish, though they may not be as durable in extreme climates. Many professionals favor oil-based decks applied during the early morning or late afternoon when temperatures are milder.

The Role of Heat-Resistant Deck Stain Technology

Innovations in stain technology have led to heat-resistant formulations that endure prolonged high temperatures. These advanced stains use special polymers and co-solvents to create a flexible, durable film over the wood. This film better accommodates wood expansion and contraction without cracking or peeling. Manufacturers now offer heat-tested products proven to resist thermal degradation for longer periods, a crucial factor in hot summer climates.

Examining Solid Versus Semi-Transparent Deck Stains for Summer Durability

Solid deck stains provide a thicker, more opaque finish compared to semi-transparent stains, which show more of the wood grain. Solid stains often contain more pigment and UV inhibitors, offering superior protection against fading and weathering. They cover imperfections effectively but may hide the natural beauty of the wood. Semi-transparent stains, while more aesthetically pleasing, may require more frequent reapplications in intense summer conditions. Evaluating the trade-offs between appearance and durability is key.

Detailed List: Factors to Consider When Selecting a Deck Stain for Summer

- UV Inhibitor Content – Ensure the stain contains proven UV inhibitors such as titanium dioxide.

- Drying Time – Choose a product with a drying time suited to your local climate.

- Color Tone – Lighter tones reflect more sunlight and reduce heat absorption.

- Oil-Based vs. Water-Based – Select the formulation that best suits your application time and durability requirements.

- Flexibility – The stain should form a flexible film that adapts to wood expansion.

- Penetration Depth – A good stain penetrates deeply into the wood for long-term protection.

- Environmental Certification – Look for products that have been independently tested for high-temperature performance.

Table: Comparison of Popular Deck Stain Options for Summer

Below is a table comparing key attributes of popular deck stain options suited for

:

Before applying any product, careful consideration of these factors will help ensure your deck finish remains resilient throughout the summer.

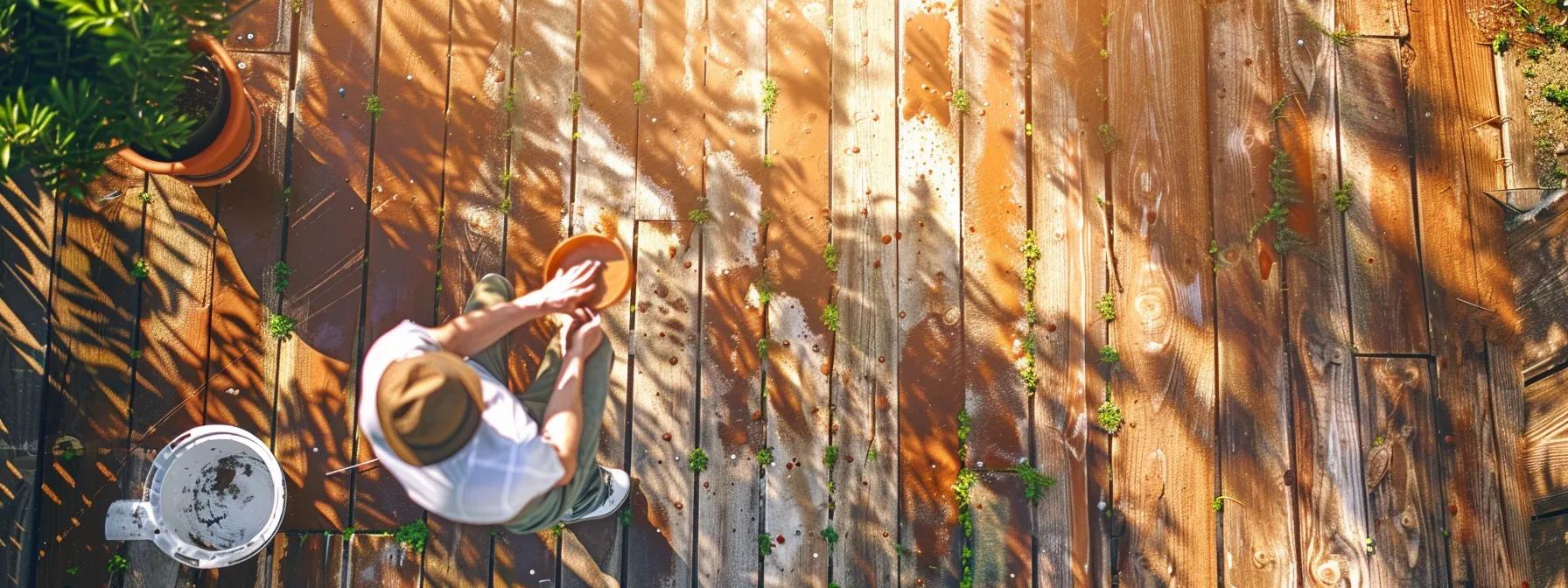

Proper Application of Deck Stain and Paint During Warm Weather

Applying deck stain and paint during warm weather requires proper planning and timing to guarantee a long-lasting finish. Professionals emphasize applying these products during cooler parts of the day to avoid rapid solvent evaporation. A clean, dry, and well-sanded deck is critical to ensuring good adhesion and minimizing traction issues.

Ideal Temperature Ranges for Applying Deck Stain and Paint

For best results, apply deck coatings when temperatures range between 50°F and 85°F. Exceeding these limits may cause rapid drying, impairing the coating’s ability to bond with the wood. Field experts recommend checking local forecasts and choosing application windows where temperatures are stable and not at their peak.

Best Times of Day to Paint or Stain Your Deck in Summer

Early mornings or late afternoons are ideal as the sun is less intense and temperatures moderate. These time frames allow the product to set in a controlled manner, and naturally lower humidity levels can improve drying times without compromising uniformity. Working in direct sunlight may cause the coating to dry excessively fast.

Preparing Your Deck Surface Thoroughly Before Summer Application

Before applying any coat: – Cleaning: Remove dirt, debris, and mildew using a pressure washer or soft washing method. – Sanding: Sand the deck to remove old coatings and create a rough surface that promotes adhesion. – Repairing: Fill any cracks or gaps with appropriate wood filler. – Drying: Allow the deck to dry thoroughly, as residual moisture can impair curing.

Techniques for Applying Deck Stain to Avoid Streaks in Direct Sun

Work in manageable sections when applying deck stain or paint in direct sun. Use thin, even coats to prevent streaks and pooling. A brush for edges, combined with a roller or sprayer for larger areas, ensures even distribution. Keeping a wet edge minimizes lap marks and uneven tones.

Ensuring Adequate Drying and Curing Times for Deck Finishes in the Heat

High temperatures can accelerate drying but may compromise proper curing. Allow extended curing times, especially in humid environments, to ensure the finish reaches full hardness and adhesion. Avoid foot traffic on the newly coated deck until it is completely cured.

Detailed List: Best Practices for Applying Deck Coatings in Warm Weather

- Check Weather Conditions – Monitor forecasts for stable temperatures and low humidity.

- Work in Sections – Divide the deck into manageable areas to maintain a consistent wet edge.

- Use Quality Tools – Invest in high-quality brushes, rollers, or sprayers.

- Apply Thin Coats – Multiple thin layers are preferable to a single thick coat.

- Allow Proper Drying Time – Follow manufacturer recommendations and extend curing times if needed.

- Maintain Clean Equipment – Regularly clean tools to prevent build-up.

- Test in a Small Area – Perform a patch test on a discreet deck section to assess adhesion and drying.

Table: Ideal Application Guidelines for Deck Coatings

Following these guidelines helps ensure your deck coating withstands summer heat while maintaining an attractive, durable finish.

Protecting Your Painted or Stained Deck From Summer Elements

After the deck is stained or painted, proactive measures are required to protect it from ongoing summer elements. Regular maintenance and targeted protective strategies prolong the finish’s life and keep the deck looking its best year-round.

The Importance of Regular Cleaning for Summer Deck Maintenance

Regular cleaning during summer is critical as dust, pollen, and debris accumulate quickly. A clean deck allows the finish to breathe and function effectively. High humidity and heat encourage mold and mildew growth, which can damage both appearance and structure. Establish a routine cleaning schedule using mild cleaners designed for wood surfaces to remove dirt before it becomes damaging.

Utilizing Shade Structures to Minimize Sun Damage on Deck Finishes

Shade structures such as umbrellas, pergolas, and awnings reduce the direct impact of sunlight on deck surfaces. Limiting UV exposure keeps the deck cooler and reduces stress on the finish. Strategic landscaping, such as placing trees or trellises, can also help reduce direct sunlight.

Strategies for Preventing Mold and Mildew Growth on Decks in Humid Summers

In humid conditions, mold and mildew risks are high. Preventative strategies include ensuring proper deck drainage, using mold-resistant cleaners, applying anti-mildew additives in stains or paints, and maintaining good ventilation. Regular inspections help catch early signs of mold or mildew so prompt treatment can prevent extensive damage.

Inspecting and Addressing Minor Damage to Deck Paint or Stain Promptly

Small cracks, chips, or peeling can quickly escalate under harsh summer conditions. Regularly inspect your deck, especially after extreme weather, to catch early signs of wear. Early intervention through spot repairs or reapplications can prevent further degradation and save time and expense.

Reapplication Schedules for Deck Stain to Maintain Protection

Deck finishes do not last indefinitely. Experts recommend applying a new coating every two to three years, with more frequent touch-ups in extreme weather regions. A regular maintenance schedule helps preserve the deck’s aesthetic appeal and prevents minor damage from becoming a major issue.

Detailed List: Key Maintenance Strategies for Protecting Deck Finishes in Summer

- Routine Cleaning – Clean your deck at least once a month.

- Shade Optimization – Install shade structures like pergolas or umbrellas.

- Mold Prevention – Use anti-mold cleansers and ensure proper ventilation.

- Regular Inspections – Check for damage after heavy rains or heatwaves.

- Touch-Up Applications – Address small cracks or chips immediately.

- Reapplication Schedule – Plan for a full re-coating every 2-3 years, with interim touch-ups.

- Proper Drainage – Ensure water does not pool on the deck.

Table: Summer Deck Maintenance Schedule

Implementing these strategies helps ensure that your deck remains protected and visually appealing throughout the summer.

Common Deck Paint and Stain Problems Caused by Summer Heat

Summer heat can lead to finish problems that affect both the appearance and performance of deck coatings. Premature fading, peeling, burst bubbles, and tacky surfaces are common issues that not only compromise aesthetics but also diminish protective capability.

Addressing Premature Fading of Deck Stain Due to Intense Sunlight

Excessive sun exposure breaks down chemical bonds in the stain, causing rapid fading, particularly in coatings lacking sufficient UV inhibitors. Homeowners can mitigate this by selecting high-quality, UV-resistant products and reducing direct sun exposure through strategic positioning and shade structures.

Managing Peeling or Blistering Deck Paint From High Temperatures

Peeling and blistering result from rapid wood expansion and contraction combined with fast-drying coatings. Proper surface preparation, using products formulated for extreme temperatures, and applying during cooler periods can help maintain adhesion.

How Rapid Drying of Deck Stain in Heat Can Cause Uneven Finishes

If deck stain dries too quickly in high temperatures, it may result in uneven coloration and patchy finishes. Working in controlled conditions and applying multiple thin layers allows for more uniform drying and a professional finish.

Dealing With Warped or Cracked Deck Boards Affecting the Finish

Extreme heat may cause wood to warp, undermining the adhesion of the coating. Cracks in warped areas provide pathways for moisture penetration, leading to further deterioration. Regular maintenance and the use of protective sealers can manage these risks.

Tackling Sticky or Tacky Deck Stain Surfaces in Humid Heat

In overly humid conditions, coatings may not cure properly, leaving a sticky finish that attracts dirt and debris. Ensuring adequate drying time and choosing products designed for humid climates can prevent this issue.

Detailed List: Common Problems and Their Remedies in Summer Deck Finishing

- Premature Fading – Use UV-resistant coatings and provide shade.

- Peeling/Blistering – Ensure proper surface preparation and apply during cooler parts of the day.

- Uneven Finishes – Use multiple thin layers for uniform drying.

- Warped Boards – Regularly inspect and reinforce with sealers.

- Cracked Surfaces – Use flexible, high-quality products.

- Sticky Finishes – Optimize humidity and ventilation during application.

- Dust and Debris – Regular cleaning prevents contamination.

Table: Common Summer Deck Finishing Problems and Solutions

Addressing these issues promptly is key to maintaining a durable and attractive deck finish, even under harsh summer conditions.

Deck Paint Versus Deck Stain Performance Under Summer Conditions

One frequent debate among experts and homeowners is whether to use deck paint or deck stain. Both options have distinct advantages and drawbacks in summer conditions, and understanding their differences can help you make an informed decision.

Durability Differences Between Paint and Deck Stain in High Heat

Deck paint forms a thicker, more protective film, but under high heat, its rigid finish is more prone to cracking and peeling as the wood expands and contracts. In contrast, deck stains penetrate the wood and create a thinner, more flexible layer that adapts better to natural movement. Although stains may require more frequent reapplication, their flexibility often results in better long-term durability under fluctuating temperatures.

Heat Absorption Characteristics of Painted Decks Compared to Stained Decks

Painted surfaces, typically darker and thicker, absorb more heat, which can accelerate deterioration. Deck stains, especially in lighter hues, absorb less heat and keep the deck cooler, thereby reducing stress on the finish.

Maintenance Requirements for Painted Decks Versus Stained Decks in Summer

Painted decks may require labor-intensive touch-ups and repainting when cracking or peeling occurs. Stained decks, with their penetrative finish, are easier to maintain, although both benefit from regular cleaning and reapplication of topcoats or sealers.

Aesthetic Considerations for Paint and Deck Stain in Bright Summer Light

Deck stains highlight the natural wood grain and offer a more organic look, while painted decks provide a uniform color range but can sometimes appear artificial. In bright summer light, stains tend to retain warmth and depth better than paint, which may fade or appear chalky.

Resistance to Peeling and Chipping Paint Versus Fading Deck Stain

Under intense summer conditions, painted finishes are more susceptible to peeling and chipping due to a compromised adhesive bond. Deck stains generally fade gradually, offering more predictable maintenance intervals.

Detailed List: Comparison Points Between Deck Paint and Deck Stain for Summer Use

- Film Thickness – Paint forms a thicker film; stain creates a thinner, flexible finish.

- Heat Absorption – Darker paint absorbs more heat; lighter stains keep surfaces cooler.

- Adhesion – Stains bond with wood fibers; paint relies on surface adhesion, making it more prone to peeling.

- Maintenance Frequency – Painted decks often need more frequent touch-ups; stains may require periodic reapplication.

- Aesthetic Appeal – Stains enhance the natural grain; paint offers versatile colors but might seem artificial.

- Durability – Stains typically perform better under heat because of their flexibility.

- Repair Ease – Spot repairs for stains are simpler than repainting large areas.

Table: Comparison of Deck Paint vs. Deck Stain Under Summer Conditions

Both deck paint and deck stain have their merits. The appropriate choice depends on the specific conditions of your deck, expected wear, and desired aesthetic. Homeowners should weigh these factors to decide which method meets both functional and visual expectations under extreme summer

.

Frequently Asked Questions

Q: What is the ideal temperature range for applying deck stain and paint during summer? A: The ideal temperature range is between 50°F and 85°F. This range helps ensure that the coating dries and cures properly without rapid evaporation, poor adhesion, or uneven finishes. Working in the early morning or late afternoon is best.

Q: How does high summer heat affect the adhesion of deck coatings? A: High heat causes rapid evaporation of solvents, leading to insufficient penetration and weak bonding with the wood. This often results in peeling, blistering, and cracking as the wood expands and contracts. Applying coatings during cooler parts of the day and using heat-resistant products can improve adhesion.

Q: Are lighter colored deck stains better in hot weather? A: Yes, lighter colored deck stains absorb less heat than darker shades, reducing wood expansion and contraction, which in turn decreases stress on the finish. This leads to a longer-lasting and more resilient coating.

Q: What maintenance tasks are crucial for preserving a deck finish during the summer? A: Regular cleaning to remove dust and debris, periodic inspections for damage, prompt touch-up repairs, and ensuring proper drainage are crucial. Using shade structures and anti-mold treatments also helps maintain the finish in prolonged summer conditions.

Q: How does deck stain compare to deck paint in terms of durability under summer conditions? A: Deck stain often performs better in summer because its penetrative, flexible nature accommodates wood movement, while deck paint, though forming a thicker film, is more prone to cracking and peeling when exposed to intense heat and UV radiation.

Q: Can I apply multiple thin coats of deck stain to improve its performance in summer? A: Yes, applying multiple thin coats is recommended over a single thick coat. This approach allows for better penetration, more uniform drying, and forms a flexible barrier that withstands thermal expansion and contraction.

Q: What are some recommended products or strategies to prevent premature fading of deck coatings in the summer? A: To prevent premature fading, use deck coatings containing high levels of UV inhibitors. Employing shading solutions such as pergolas or outdoor umbrellas and regular maintenance, including reapplication of a protective topcoat every few years, will further extend the finish’s longevity.

Final Thoughts

Maintaining a deck’s appearance and durability during the summer requires careful attention to heat, humidity, and sunlight. This article has detailed the impacts of high temperatures on deck coatings, provided expert advice on product selection, and outlined best practices for application and ongoing maintenance. By choosing products with adequate UV protection and formulations optimized for hot weather—and by scheduling applications during the coolest parts of the day—homeowners can significantly prolong the life of their deck’s finish. Consistent upkeep and timely repairs ensure that the deck remains vibrant, secure, and appealing through every season.